How to Measure and Replace Yacht Standing Rigging: A Comprehensive Guide

Replacing standing rigging on a yacht may seem daunting, but following a structured approach can make the process manageable. Whether you choose to replace rigging with the mast up or down, accurate measurements and careful planning are essential.

Step-by-Step Guide to Measuring and Replacing Yacht and Dinghy Rigging

1. Decide Whether to Work with the Mast Up or Down

- Mast Down: If time and resources allow, lowering the mast simplifies the process. It provides better access for inspection and measurement.

- Mast Up: If the mast remains stepped, each wire should be ordered slightly over-long, with the top terminal swaged. The bottom end can be finished in situ using a swage less terminal.

2. Inspect Existing Standing Rigging

- Check for signs of wear, corrosion, and deformation.

- Take photos and mark tension settings for reference.

- Consider any design or specification alterations.

3. Gather Measurement Tools

- Tape measure or calibrated ruler

- Tension gauge for assessing wire tension

- Notepad or digital device for recording measurements

4. Measuring Standing Rigging

- Forestay & Backstay: Measure from the masthead attachment point to the deck fitting.

- Shrouds: Measure from the mast attachment point to the chainplate.

- Turnbuckles & Terminals: Include their lengths in your measurements.

- Rigging Screws: Ensure adjustment range is considered.

- Measuring Wire Diameter

- Use vernier calipers to measure the wire diameter.

- Ensure the correct diameter is recorded, as terminals are manufactured to fit specific wire sizes.

- Measuring Rigging Length

- Lay the rigging flat and taut.

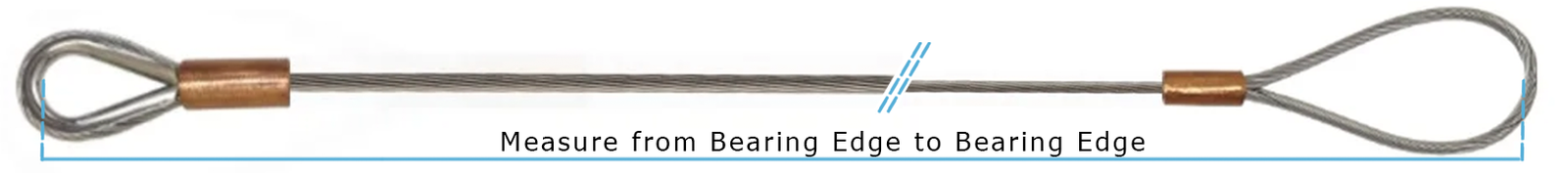

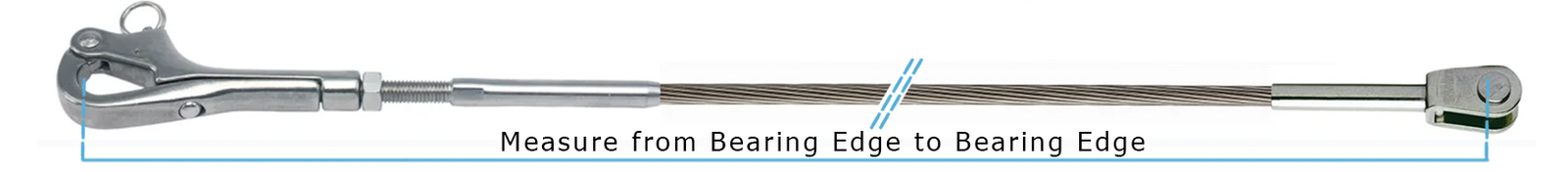

- Measure from bearing surface to bearing surface (e.g., from the eye of one terminal to the eye of the opposite terminal).

- The bearing edge is the point/surface at the end of a termination that will take the load i.e. the inside edge of an eye.

- Examples of this are shown below:

- If ordering rigging with a rigging screw or turnbuckle, measure the full assembly with screws fully closed unless otherwise specified.

- Our website will accept a length to 3 decimal points. However, this is not usually practicable. We aim to produce your rigging to a tolerance of + or - the diameter of the wire

- Please take extra care when ordering because once a custom built product has been started (cut) it can neither be cancelled nor returned for a refund.

5. Ordering Replacement Standing Rigging

- If the mast is down, each wire can be ordered with swaged terminals at both ends.

- If the mast remains stepped, the bottom terminal should be fitted in situ using a swage less terminal.

6. Standing Rigging Checklist

- Tune and tension check on existing rigging.

- Close inspection of all components, including measuring diameters.

- Determine possible improvements.

- Order process for mast unstepped vs. mast remaining stepped.

7. Installation Considerations

- If replacing rigging screws, ensure compatibility with existing fittings.

- Consider split, adjustable, or insulated backstays.

- Account for forestay foibles caused by headsail furler fittings.

Conclusion

Accurate rigging measurements and careful planning ensure a smooth replacement process. Alternatively, for standing rigging replacement, please consult our rigging experts at Martin Leaning Masts & Rigging or use our Custom Rigging Calculator.