Hand Fitted instead of machined swage – 5 Easy Steps to Instant Rigging

The Sta-Lok Self-fit terminals are a simple mechanical method of terminating 1×19, 7×7, 7×19 and compacted strand wire ropes. Suitable for both right-hand lay and left-hand lay constructions.

The self-fit terminals can be fitted on-site using very simple hand tools, this means no pre-measurement or site visit is necessary. The Sta-Lok terminal will work under constant loading and variable shock loading. Manufactured from 316 stainless steel. All Sta-Lok terminals are reusable* requiring no servicing, providing long life and very low maintenance costs.

*A new wedge component must be used.

Each terminal comes with fitting instructions; however, please find the below fitting instructions for reference.

- Sta-Lok Terminals have been designed for use with stainless steel wire ropes. They should not be used with Galvanized wire ropes because rapid galvanic action will cause the wire rope to corrode and fail.

- Sta-Lok Terminals are not suitable for use with wire ropes with fibre cores.

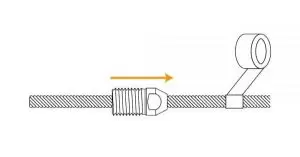

Step 1.

Slide socket component over the wire. TIP: Wind tape around wire approx. 12″ (300mm) from the end. This will prevent the socket from sliding down the wire.

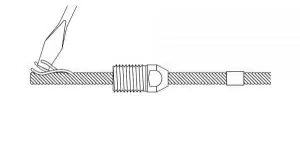

Step 2.

Unravel outer strands 2″ to 3″ (50-76mm) to expose the central core.

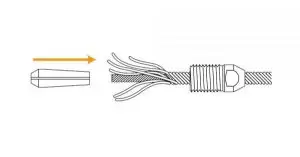

Step 3.

Slide wedge component over a central core of wire rope.

Step 4.

Reposition outer strands.

Turn outer strands either clockwise or anti-clockwise, depending on the lay of the wire, around the wedge.

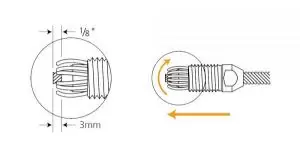

Ensure approx. 1/8″ (2-3mm) of the central core protrudes from the end of the wedge.

Outer strands should be evenly situated around the wedge. Work with care to ensure that a strand does not slip into the slit of the wedge. TIP: Push the socket towards the end of the wire, while repositioning the outer strands, this will help control.

When wire strands are in position, push the socket firmly, as indicated, to hold wires in position.

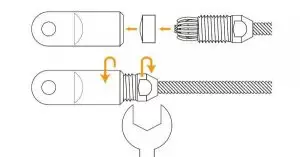

Step 5.

Final Assembly

Ensure the former component sits at the bottom of the end fitting. Screw socket assembly into end fitting and tighten with spanners. The assembly is now complete.

TIP: The wire does not require undue force to terminate it. Each terminal comes with fitting instructions.